Our Services

End-to-end injection mold tooling services designed for small molding shops that need offshore cost savings without the offshore headaches. Part design and prototyping also available.

Offshore Injection Mold Tooling (Asia)

High-quality injection molds manufactured in Asia with USA-based engineering oversight and project management.

• Full USA-based communication and project coordination

• Typical 20-30% cost savings vs USA tooling (up to 50%)

• Quality gates at every stage of the build

• Proven parts before tools ship to USA

Tool Design & DFM Analysis

Comprehensive Design for Manufacturing reviews to optimize your

parts for injection molding and reduce tooling costs.

• CAD review and feasibility analysis

• Gate location and runner optimization

• Moldflow simulation recommendations

• Detailed tool design review and approval before build starts

Rapid Prototyping (3D Print / Soft Tooling)

Fast-turnaround prototyping options to validate your design before committing to production tooling.

• SLA, SLS, and MJF 3D printing

• CNC machining for functional prototypes

• Soft tooling for 10-1000 parts

• Bridge tooling for market testing

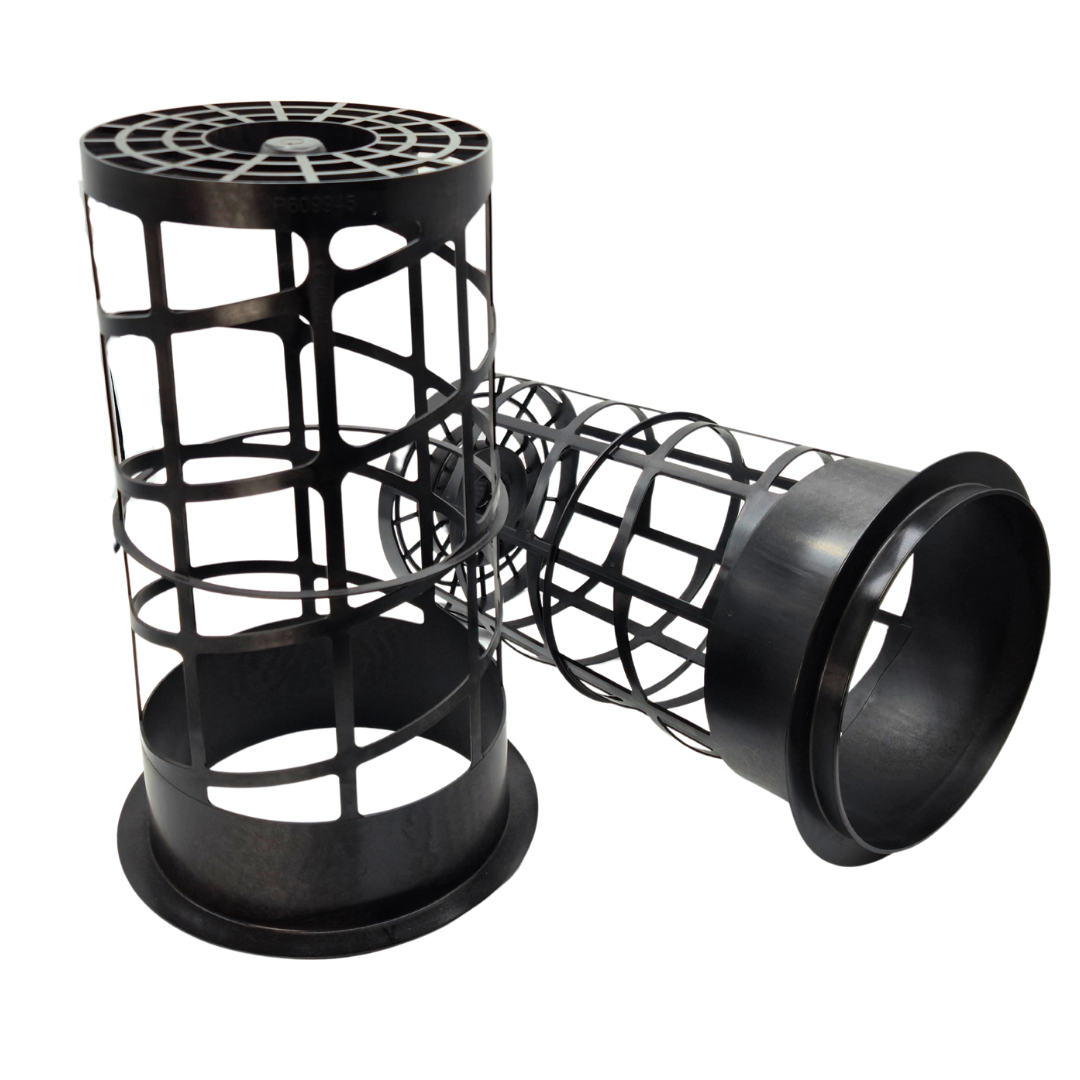

Prototype & High-Volume Production Tooling

From low-volume prototype tools to multi-cavity production molds for millions of parts.

• Prototype Tools: 1-2 cavity, 10K-100K shot life

• Production Tools: Multi-cavity, 500K+ shot life

• Family molds and multi-material overmolding

• Hot runner systems and automation integration

Tool Build Management & Oversight

Active project management throughout the tool build to ensure quality, timeline, and budget compliance.

• Weekly status updates and progress photos

• Quality control and dimensional verification

• Engineering change order management

Sampling & Qualification (TO/T1/T2)

Comprehensive sampling and testing programs to prove tool quality before shipment to USA.

• TO (First Shot): Initial part review, fit checks, dimensional verification

• T1 (Engineering Sample): As needed for adjustments from T0 samples

• T2 (Production Sample): Full qualification run with final surface finish applied

• Parts shipped to you for approval before tool ships

Tool Transfer to USA

Complete logistics management for tool delivery to your facility or molding partner.

• Freight forwarding coordination

• Post-delivery support, spare parts, as needed

Engineering Design for Injection Molded Parts

Full part design services for customers who need engineering support from concept to production.

• CAD modeling and detailed part drawings

• Material selection and testing coordination

• Design optimization for moldability

Industries We Serve

Essentially any industry that uses injection molded parts

Automotive

Aerospace

Industrial Equipment

Consumer Products