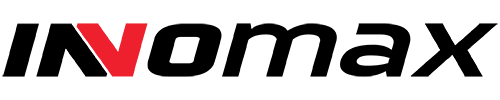

Custom Injection Mold Tooling

Offshore tooling programs engineered, managed, and validated by U.S.-based experts — with full project control from CAD to production approval.

Engineering Resources & Project Oversight

Every tooling program is managed as a controlled engineering project — not a factory handoff.

- Typical 6–8 week lead time to first T1 samples after mold design approval

- Tooling support for 50-ton to 3500-ton press applications

- Moldflow analysis applied during DFM when required to mitigate risk early

- U.S.-based senior project managers serving as your primary point of contact

- Experienced in-house mold designers supporting complex tooling architectures

- First Article Inspection (FAI) reports provided for every molded component

- Pre-shipment mold inspections conducted by experienced mold makers

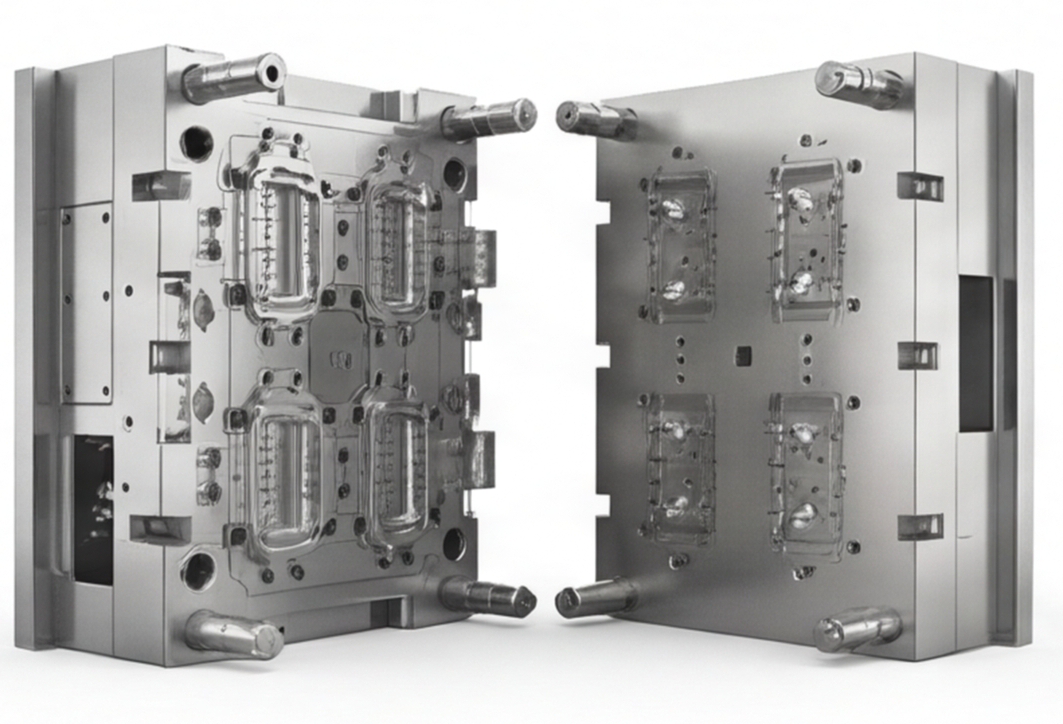

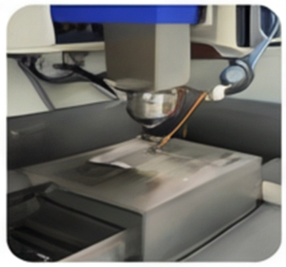

Precision CNC Machining

Moldflow Analysis

Detalled Mold Inspection

Mold Design & Manufacturing Capabilities

We support a wide range of custom injection mold designs — from straightforward production tools to highly complex, multi-feature builds.

For full tool visualization

Detailed 2D drawings

For individual components, provided as required

Single-cavity, multi-cavity, and family tooling

Configurations

Tool steel selection

Matched to expected production volume and lifecycle

Insert molding and overmolding

Tooling solutions

Hot tip, hot manifold, and valve gate systems

For optimised runner performance

Surface finishes to Mold-Tech / VDI standards

Including laser and EDM texturing

Advanced tooling solutions

For complex geometries and mechanisms

Manufacturing resources:

- Modern 5-axis CNC machining centers

- Wire EDM and sinker EDM machining for complex features

- Precision gun drilling for optimized cooling performance

Our Offshore Tooling Partner

Our long-term offshore tooling partner operates a dedicated precision tooling facility focused on injection mold manufacturing for global customers.

- 2,000+ square meter dedicated tooling facility

- 50+ skilled personnel, including senior engineers and QA staff

- In-house CNC machining, EDM, grinding, metrology, and injection equipment

- Tooling capacity of approximately 50 molds per month

- Customers primarily in the United States, Canada, and Germany

- DME and HASCO compatible mold standards

- Tooling types include prototype molds, cold runner molds, hot runner molds, unscrewing mechanisms, overmolding, insert molds, and MUD systems

- Maximum mold weight approximately 8 tons

Why Innomax for Custom Tooling

-

U.S.-Based Engineering Leadership

Every project is led by experienced U.S. engineers—ensuring clarity, accountability, and precision from day one.

-

Daily Offshore Oversight

Our teams provide continuous, hands-on oversight of offshore manufacturing—no gaps, no guesswork.

-

Transparent Documentation & Inspection Reports

You receive clear documentation, inspection photos, and detailed reports at every milestone.

-

Strict Quality Gates Before Shipment

No tool ships without passing defined quality checkpoints—protecting your timeline and investment.

-

Offshore Cost Savings Without Losing Control

Enjoy global manufacturing savings while maintaining full visibility, communication, and decision-making authority.

Ready to Discuss Your Tooling Project?

Get a detailed quote and a clear project timeline — no guesswork.